- Intensify general satisfaction with the service.

- Improve the brand´s reputation.

- Drag new customers.

- Speed up your cash flow.

- Avoid breaches of contract

For all those reasons, it is essential to have a well-optimized supply chain.

However, there are industries in which the manufacturing time is quite large, making it difficult to have a consistent and fast delivery time. For example, that is the case of the automotive sector and one of our clients, Seat, wanted a solution.

Data set

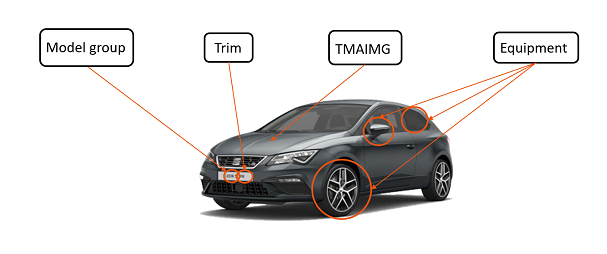

In SEAT’s case, every car has four different configuration levels: model group, trim, TMAIMG and equipment. Thus, counting every possible combination, there are 10,000 total possibilities for each car.

That amount of combinations makes it really hard to pre-manufacture cars so that the delivery time can be shortened. That is why Seat contacted us to develop an artificial intelligence project to reduce the delivery time of their cars.

Data analysis

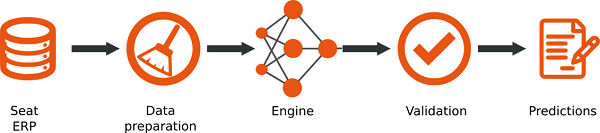

Our team studied how to predict the orders for the next three months based on Seat’s historical sales data (past three years). And we decided to build a software tool personalized for Seat that uses neural networks to predict sales.

Before building the software, it was necessary to pre-process all the data, so the data set you imported to the software had the best quality possible (remove unused items, remove certifications, update old TMAIMGs, identify and remove fleets, etc.). As a result, we managed to reduce the data set from 100,000 rows to 70,000 rows.

After preparing the data set, it was time to develop the predictive software. First, it applies neural networks with a self-configurable feed. Then, the software uses the Regularized Minkowsky loss index and the Quasi-Newton training algorithm to get the most use out of that prepared data set.

Later, the Apriori algorithm is used to obtain the most frequent combinations in the most optimal way. And finally, the prediction is validated in three different levels (Trim, TMAIMG and Combination) by calculating the error and the accuracy.

The total mean accuracy when predicting sales is 88%, indicating a good performance for Seat’s predictive model in their order system.

Conclusions

Before applying artificial intelligence to their logistics, Seat only delivered 50% of their orders in less than one month.

By using Artelnics’ predictive model technology, Seat managed to reduce the delivery time of 50% of their orders to 2-3 weeks and made them the first company to guarantee the delivery time of a car in between 2 to 3 weeks. They called this solution Fast Lane, and granted them a great competitive advantage over the other brands.